Understanding Machine Vision: Technology, Applications, and Future Trends

1. Introduction to Machine Vision

What is Machine Vision?

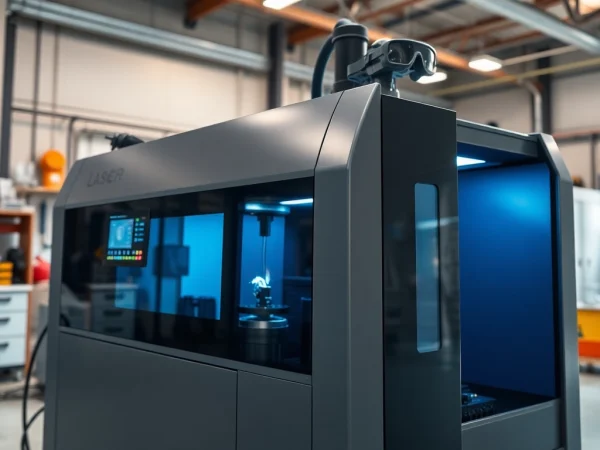

Machine vision is a pivotal technology that employs cameras and software to enable machines to interpret and act upon visual data from their environment. This capability extends beyond simple image capture; it encompasses a suite of techniques that facilitate automatic inspection, analysis, and decision-making. Overall, machine vision can be understood as the technology that empowers machines not just to “see,” but to “understand” the visual inputs, making real-time assessments based on predefined criteria.

Primarily used in industrial settings, machine vision systems integrate optical, mechanical, and software components that work cohesively to accomplish tasks traditionally performed by human inspectors. An example can be seen in quality control processes, where machine vision is critical for ensuring products meet necessary standards. As the demand for automation grows, machine vision has become an indispensable tool across various sectors, drastically improving efficiency and accuracy.

Historical Context and Development

The roots of machine vision can be traced back to the early 1970s, when the first rudimentary systems were developed to assess simple characteristics like shape and size. Over the decades, the evolution of semiconductor technology, together with advances in computer processing power and image acquisition techniques, has significantly transformed the field.

Initially constrained by technological limitations, the systems of the late 20th century were often limited to basic tasks within controlled settings. However, with the explosion of digital imaging technology and the development of sophisticated algorithms in the early 2000s, machine vision systems transitioned from niche applications into mainstream functionalities. Today, they are integral to a wide range of industries including automotive manufacturing, pharmaceuticals, electronics assembly, and food production.

Importance in Modern Industry

Machine vision technologies play a critical role in modern industry, significantly impacting operational effectiveness. With the advent of Industry 4.0, the use of machine vision has been amplified, facilitating not just automation but also intelligent decision-making processes. In logistics, for instance, machine vision is used for package sorting and tracking, while in manufacturing, it enhances quality control by enabling real-time defect detection and precision measurement. Thus, machine vision serves as both a foundational technology for automation and a catalyst for innovation, driving improvements in cost-efficiency and responsiveness to market demands.

2. Core Components of Machine Vision Systems

Cameras and Sensors

At the heart of any machine vision system is the camera, which acts as the visual input device. Machine vision cameras differ from regular consumer cameras in that they are specifically designed to capture high-resolution images quickly and accurately. There are several types of cameras used in machine vision systems, including:

- CCD Cameras: Charged Coupled Device cameras are known for their exceptional image quality and sensitivity to light, making them suitable for various industrial applications.

- CMOS Cameras: Complementary Metal-Oxide-Semiconductor cameras offer lower power consumption and faster processing speeds, beneficial for high-speed manufacturing environments.

- Infrared Cameras: These are employed in applications requiring thermal imaging, useful for identifying hot spots or assessing temperature variations.

The choice of camera can have a significant impact on the performance of the machine vision system. Integrating high-quality sensors enables accurate image processing, which is essential for reliable assessments and decision-making.

Lighting Techniques and Their Impact

Proper lighting is crucial in enhancing the effectiveness of machine vision systems. The way objects are illuminated can dramatically influence the clarity and quality of images captured. Different lighting techniques can be applied depending on the specific requirements of the inspection task. For instance:

- Backlighting: This technique emphasizes the edges of objects, useful for detecting flaws in opaque items.

- Diffuse Lighting: It minimizes shadows and glare, supporting more uniform lighting across the object surface.

- Structured Lighting: This method projects patterns onto the object, enabling 3D shape recognition and providing depth information.

Strategies for selecting lighting should consider the material, texture, and color of the inspected object to attain optimal image quality. A well-designed lighting setup can substantially reduce noise and enhance the quality of feature recognition.

Processing Units and Software Algorithms

The processing unit is responsible for interpreting the visual data captured by the camera. Machine vision algorithms analyze the images to extract useful information, including defect detection, object recognition, and measurement analysis. Various algorithms engage with the data based on the complexity of the tasks at hand. Common types include:

- Template Matching: This technique compares captured images against stored templates to locate specific features, commonly used in assembly verification.

- Edge Detection: Focusing on identifying object boundaries for determining shapes, this method assists in precise measurements for quality control.

- Deep Learning: Increasingly applied to machine vision, deep learning algorithms utilize neural networks to improve recognition accuracy in complex scenarios, such as identifying multiple defects on products.

A robust processing architecture allows machine vision systems to perform complex operations quickly, enabling real-time analysis. The choice of software is equally crucial; it should support various image processing algorithms and integrate seamlessly with hardware components.

3. Applications of Machine Vision Technology

Quality Control and Inspection Processes

Quality control remains one of the most significant applications of machine vision technology. Whether assessing the characteristics of manufactured components or ensuring that packaged goods meet regulatory standards, machine vision systems provide a reliable means of inspection. With rapid advancements in imaging technology, machine vision can conduct quality assessments in real-time, allowing for immediate rectifications. Systems can be configured to:

- Detect surface defects (scratches, dents, discoloration).

- Ensure correct labeling and packaging of goods.

- Verify the proper assembly of components during manufacturing stages.

By employing automatic inspection methods, manufacturers can substantially reduce human error, increase throughput, and enhance product reliability, making machine vision integral to quality assurance strategies.

Automated Assembly Guidance

Machine vision systems are also leveraged for guiding assembly processes. In complex manufacturing environments, where precision is crucial, machine vision helps position components accurately and automate assembly tasks. For instance, in automotive assembly lines, machine vision can assist robotic arms by providing feedback on the precise location of parts, ensuring that every component is aligned correctly before the next steps are executed. This not only speeds up the production process but also minimizes the risk of errors and costly recalls.

Barcode Scanning and Logistics

In logistics and inventory management, machine vision technology facilitates quick barcode scanning, enabling seamless tracking and management of goods. Systems equipped with machine vision cameras can quickly read different types of barcodes and QR codes, facilitating accurate inventory counts and shipment processing. The ability to capture multiple codes in a single view speeds up workflows, helping companies to improve their operational efficiency and accuracy.

4. Benefits and Challenges of Implementing Machine Vision

Improving Efficiency and Accuracy

The most prominent advantage of implementing machine vision systems is the notable increase in operational efficiency and accuracy. Automated inspections conducted by machine vision can process hundreds or thousands of items per minute, significantly faster than human inspectors without tireless effort. In addition, machine vision reduces human error, ensuring a higher level of detail and accuracy in inspections. As a result, companies witness enhanced productivity, lower costs associated with returns and rework, and improved overall quality of their products.

Cost Considerations and ROI

While the implementation of machine vision systems may involve a hefty initial investment, the long-term ROI (Return on Investment) justifies this expense for many organizations. Considerations for cost include:

- Technology Investment: Costs associated with cameras, lighting, and software can vary significantly based on features and capabilities.

- Integration Costs: Expenses incurred during the integration of machine vision systems with existing workflows should not be overlooked.

- Maintenance and Upkeep: Ongoing costs may arise for maintenance, software updates, and hardware upgrades.

Despite the expenses, companies that carefully assess their needs and conduct cost-benefit analyses are often able to demonstrate strong ROI through improved product quality and reduced labor costs over time.

Overcoming Technical Limitations

Implementing machine vision technology is not without its challenges. Organizations may face technical limitations, including:

- Environmental Factors: Variations in lighting, dust, and matting surfaces can interfere with image quality, affecting system performance.

- Software Complexity: Selecting the appropriate algorithms and tuning parameters for specific tasks can require advanced expertise.

- Hardware Limitations: Choosing the appropriate camera and lighting solutions is vital, as subpar components can lead to inadequate results.

To overcome these challenges, companies must invest time in researching equipment and tailor machine vision systems to fit their specific environments and operational needs. Continuous monitoring and adjustments can enhance system performance as needed.

5. Future of Machine Vision Technology

Advancements in Artificial Intelligence Integration

The intersection between machine vision and artificial intelligence (AI) represents the frontier of innovation in this field. By integrating AI and machine learning with machine vision systems, organizations can enhance their capabilities significantly. For instance, AI can assist in improving image processing algorithms, enabling the system to learn and adapt from previous experiences. This ability to “learn” means that machine vision can become increasingly effective in identifying defects and making decisions based on more complex scenarios than previously possible.

Emerging Trends in Industrial Automation

The machine vision landscape is witnessing rapid advancements, particularly in the realms of automation. The continued rise of IoT (Internet of Things) devices and interconnected systems allows for greater data sharing across manufacturing ecosystems. Enhanced connectivity can propel machine vision systems to new levels of responsiveness and efficiency, paving the way for smart factories where machines operate autonomously while adapting in real-time to evolving conditions. Companies embracing these trends can position themselves at the forefront of competitive innovation.

Long-term Impact on Workforce and Processes

As machine vision technology continues to evolve, its impact on the workforce and manufacturing processes will be profound. While there are valid concerns regarding job displacement, it is essential to view machine vision as a facilitator of higher-value roles rather than as a replacement. By automating mundane tasks, employees may be freed to engage in more complex and strategic activities requiring human judgment and creativity. Anticipating these shifts and preparing to reskill the workforce will be essential for organizations in navigating the future landscape of work shaped by machine vision technologies.