Enhancing Performance with the Right Downpipe B58 Installation Guide

Understanding the Importance of Downpipe B58

The downpipe b58 plays a critical role in the performance and efficiency of a vehicle, particularly in BMW models equipped with the B58 engine. This component is responsible for directing exhaust gases away from the engine, which directly influences power output, throttle response, and overall engine efficiency. Understanding its significance is vital for anyone looking to enhance their vehicle’s capabilities.

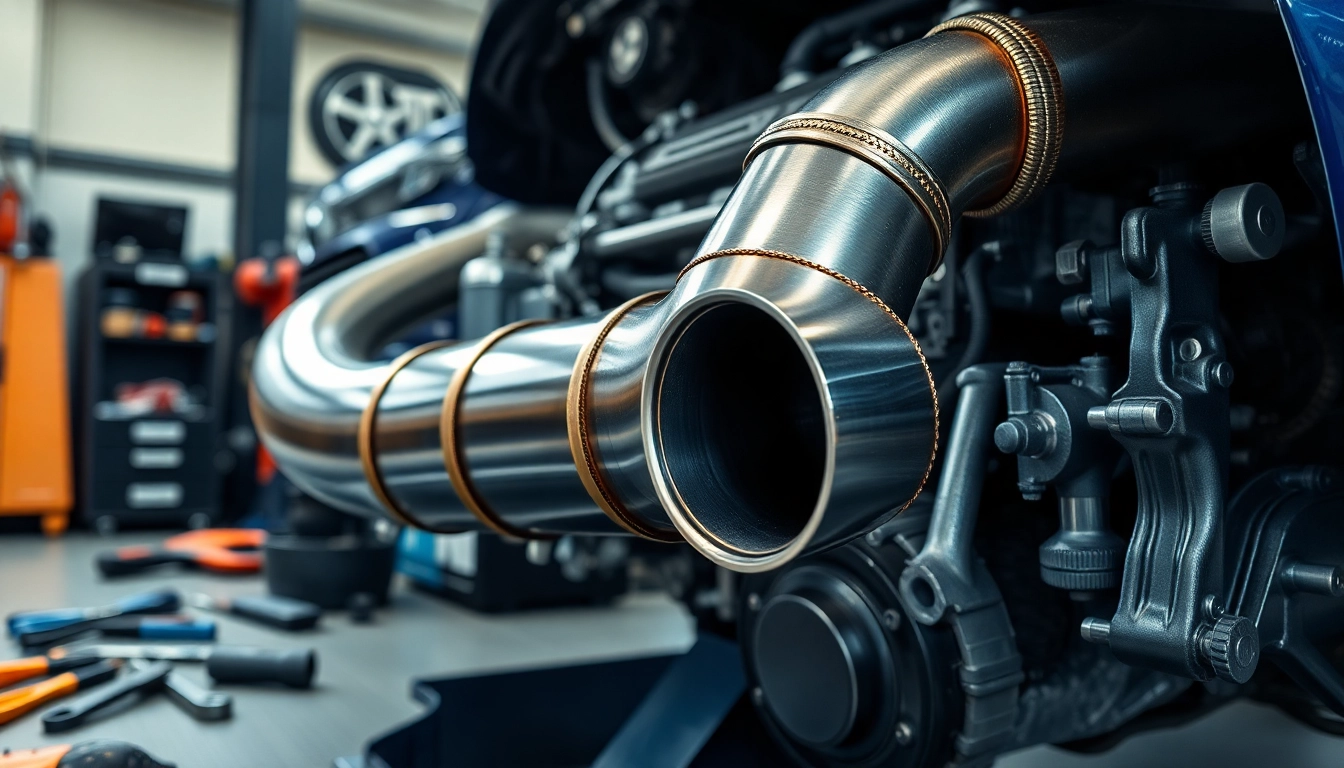

What is a Downpipe B58?

A downpipe is a segment of the exhaust system that connects the turbocharger to the rest of the exhaust piping. Specifically designed for the B58 engine, popular in multiple BMW models, the downpipe b58 is engineered to optimize exhaust flow, reducing back pressure and allowing for a more efficient turbo operation. A well-designed downpipe can significantly enhance the performance characteristics of the B58 engine, particularly under high-load scenarios.

Benefits of Upgrading to a Downpipe B58

Upgrading to a performance-oriented downpipe b58 yields numerous advantages:

- Improved Power Output: By reducing exhaust restrictions, a downpipe can lead to increased horsepower and torque.

- Enhanced Turbo Response: A less restrictive exhaust path allows for quicker spool times, which improves throttle response.

- Weight Reduction: Many aftermarket downpipes are made from lighter materials, contributing to overall vehicle weight savings.

- Better Sound: A performance downpipe enhances the exhaust note, creating a more aggressive sound that many enthusiasts appreciate.

- Increased Fuel Efficiency: More efficient exhaust flow can lead to better fuel economy under certain driving conditions.

Key Features to Consider When Choosing a Downpipe B58

When selecting a downpipe for the B58 engine, several factors should be considered:

- Material: Stainless steel is a common material choice due to its durability and resistance to corrosion.

- Design Type: Options include catless or catted designs, with each offering distinct benefits related to emissions and sound.

- Diameter: Downpipes typically come in various diameters, with larger ones allowing for better flow but potentially at the cost of sound and emissions compliance.

- Fitment: Ensure the downpipe is compatible with your specific B58 model to avoid installation issues.

- Brand Reputation: Opt for manufacturers known for quality and performance enhancements to ensure reliability.

Installation Steps for Downpipe B58

Tools and Preparation Required for Downpipe B58 Installation

Installing a downpipe b58 requires a few specific tools:

- Socket set (including deep sockets)

- Torque wrench

- Jack and jack stands or ramps

- Wrenches

- Vibrant exhaust pipe cutter (if needed)

- Safety goggles and gloves

- Replacement gaskets (if necessary)

Prior to installation, ensure the vehicle is on a flat surface and that the exhaust is cool to avoid burns.

Step-by-Step Guide to Installing Downpipe B58

The installation process can vary slightly based on the model, but the general steps include:

- Safety First: Secure the vehicle with a jack and jack stands or ramps. Wear proper safety gear.

- Remove the Under Shield: If equipped, remove any under trays to access the downpipe area below.

- Disconnect the Battery: To prevent electrical shorts, disconnect the negative terminal of the battery.

- Unbolt the OEM Downpipe: Remove the existing downpipe by loosening the bolts connecting it to the turbo and the rest of the exhaust.

- Remove the Old Downpipe: Extract the old unit carefully to avoid damaging surroundings.

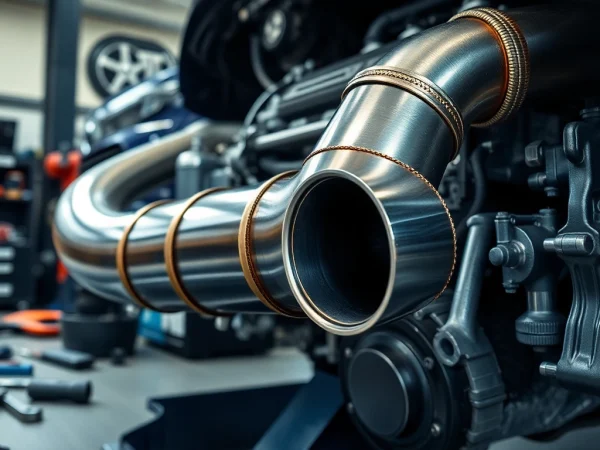

- Fit the New Downpipe: Position the new downpipe b58 in place, ensuring it fits snugly against the turbo and the exhaust system.

- Secure the Connection: Bolt the downpipe in place, and make sure to use new gaskets if required.

- Reconnect Everything: Reattach the under shield, battery terminal, and any other components removed during the process.

Common Mistakes to Avoid During Downpipe B58 Installation

To ensure a smooth installation experience, avoid these common pitfalls:

- Over-tightening Bolts: This can lead to thread stripping or cracks in the downpipe.

- Poor Gasket Alignment: Misalignment can cause exhaust leaks, so be meticulous in alignment.

- Neglecting to Recheck Connections: Before starting the vehicle, ensure all connections are secure.

- Ignoring Local Emissions Laws: Make sure your installation complies with local emissions regulations, especially if you choose a catless design.

Performance Upgrades Associated with Downpipe B58

Expected Performance Enhancements from Downpipe B58

When upgrading to a downpipe b58, users can anticipate notable performance enhancements. Typically, users report increases in horsepower ranging from 10 to 30 HP depending on supporting mods, tuning, and the specific make of the downpipe. This increase is primarily due to the reduction in exhaust back pressure, which allows the turbocharger to spool faster.

How Downpipe B58 Affects Turbo Response and Exhaust Flow

The downpipe’s design directly influences the turbo’s reaction time. With a more efficient exhaust flow enabled by a quality downpipe, the turbo can reach optimal boost levels quicker. This boost in efficiency is essential for achieving the desired performance, especially in high RPM situations where every fraction of a second counts.

Comparing Different Types of Downpipe B58 for Performance

When considering performance, the primary variants in downpipes are:

- Catless Downpipes: These eliminate the catalytic converter, providing maximum exhaust flow and a significant increase in power but may not meet emissions regulations.

- Catted Downpipes: These include a high-flow catalytic converter that balances power output with emissions compliance, making them suitable for street use.

Choosing between these two options largely depends on your intended use of the vehicle and local laws regarding emissions.

Maintenance and Care for Downpipe B58

Routine Checks to Ensure Downpipe B58 Performance

Periodic inspection of the downpipe b58 is crucial for maintaining optimal performance. Check for:

- Signs of wear or corrosion

- Leaks at joints or connections

- Any unusual exhaust sounds indicating blockage or restriction

Establishing a routine check after every few thousand miles can ensure any arising issues are caught early.

Cleaning and Maintenance Techniques for Downpipe B58

Proper maintenance of the downpipe includes:

- Debris Removal: Regularly check and clean off any debris or buildup that may restrict flow.

- Apply High-Temperature Coating: If applicable, a high-temp ceramic coating can enhance insulation and longevity.

- Monitor Exhaust Smell: A strong smell of fuel or exhaust in cabin may indicate a leak in the downpipe that requires attention.

Signs Your Downpipe B58 Needs Replacement

Recognizing the signs of failure is crucial. Common indicators include:

- Rattling noises or excessive vibration

- Decreased engine performance or responsiveness

- Visible cracks or rust

- Failed emissions tests (for catted downpipes)

If any of these symptoms are noticed, consultation with a professional or immediate inspection is recommended.

Making Informed Decisions About Your Downpipe B58

Cost Considerations for Downpipe B58 Upgrades

The cost of upgrading to a downpipe b58 can vary significantly based on material, design, and brand. Generally, prices range from a few hundred to over a thousand dollars. Additionally, consider installation costs if not doing it yourself. Weighing the potential performance gains against the cost will help make a well-informed decision.

Choosing the Right Installer for Downpipe B58

If you opt for professional installation, select a technician experienced in performance vehicle upgrades. Look for reviews or testimonials to gauge their expertise. The quality of installation can significantly impact the benefits derived from the downpipe upgrade.

Long-Term Benefits of a Quality Downpipe B58

Investing in a high-quality downpipe b58 can lead to long-term advantages for performance enthusiasts. Beyond immediate power gains, a quality downpipe enhances the longevity of turbo components due to reduced stress and improves overall engine efficiency. More importantly, a well-installed downpipe maintains proper emissions compliance, ensuring your vehicle remains roadworthy.